Ultrasonic Gas Meter

It has the advantages of high accuracy, high reliability, high security, wide range ratio, good durability, compact size, etc.

The ultrasonic gas meter is a new generation of intelligent electronic measuring apparatus, which uses the flight time difference of ultrasonic waves in the medium between the upstream and downstream for measurement. It has the advantages of high accuracy, high reliability, high security, wide range ratio, good durability, compact size, etc. It can be widely used in gas measurement for residential users, industrial and commercial users. The ultrasonic gas meter can customize temperature and pressure compensation function, and can effectively solve the traditional mechanical gas meter due to temperature and pressure changes caused by the measurement loss, which helps gas companies to reduce the supply and sales difference. Techen Technology's ultrasonic smart gas solution integrates ultrasonic metering technology and Internet of Things technology in depth, bringing the metering performance, safety and convenience of ultrasonic gas meters to the extreme. It comprehensively meets the business needs of gas companies and realizes the refinement management of gas companies.

High metering performance: with the adoption of a unique algorithm, it meets the high precision metering requirements of different media

High security: it can detect anomalies such as small flow leakage, extra-large flow, long-time constant flow, long-term unused gas, illegal meter dismantling and reverse flow, etc., it supports the function of shutting off the valve and reporting to the system at the same time to ensure gas safety in case of an anomaly.

High sensitivity: high sensitivity within the range of the whole series (G1.6-G4), effectively reducing the difference between supply and sales and ensuring the fairness of measurement

High reliability: reliable long-term operation, stable measurement throughout the life cycle because of no moving mechanical parts

Wide range ratio: within the full range of flow, high-precision metering can be achieved to meet the needs of different scenarios such as heating and daily lives

Temperature and pressure compensation: built-in high-precision temperature sensor and pressure sensor realize the real-time correction of the metering data, so as to ensure the fairness of metering

Smart metering: by deeply integrated with IoT technology, it supports remote meter reading, anomaly processing, remote price adjustment, tiered gas pricing, remote valve control, remote firmware upgrade and other functions, as well as supporting multiple settlement methods and payment methods

|

TECHNICAL PARAMETERS |

|||

|

Item content |

Parameter index |

||

|

Specifications and models |

G1.6 |

G2.5 |

G4 |

|

Flow range (m3/h) |

0.016-2.5 |

0.025-4 |

0.04-6 |

|

Measurement class |

Class 1.5 (class 1.0 customizable) |

||

|

Pressure loss (Pa) |

≤250 |

||

|

Maximum working pressure (KPa) |

20 |

||

|

Working temperature (℃) |

-25 ~ +55 |

||

|

Relative humidity |

≤95%RH |

||

|

Atmospheric pressure (KPa) |

86 ~ 106 |

||

|

Valve |

Built-in motor valve |

||

|

Power supply mode |

Alkaline battery (6V)/lithium battery(3.6V) |

||

|

Battery service life |

≥12 months/≥10 years |

||

|

Protection class |

IP65 |

||

|

Explosive-proof grade |

Ex ib II B T3 Gb |

||

|

Communication mode |

NB-loT/LoRa/infrared |

||

|

Other |

Temperature compensation and pressure compensation (optional) |

||

a. Abnormal flow: intelligently identify the measurement anomaly and shut off the valve

b. Anti-gas theft: anti-reverse installation and anti-demolition meter

c. Settlement mode: flexible choice of meter end billing or background settlement mode

d. Historical data storage: record the hourly consumption, daily consumption, monthly consumption

e. Other functions: support tiered gas pricing, remote meter reading, remote valve control, active alarm in case of an anomaly, remote firmware upgrade, optional temperature compensation and pressure compensation

|

Ultrasonic Water/Gas Meter |

|||||||

|

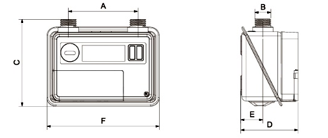

DIMENSIONS |

|

||||||

|

—— |

|||||||

|

Model |

A |

B |

C |

D |

E |

F |

|

|

G1.6 |

130 |

W30*2 |

163 |

107 |

41 |

206 |

|

|

G2.5 |

|||||||

|

G4 |

|||||||

|

Unit: mm |

|||||||

|

|

|||||||